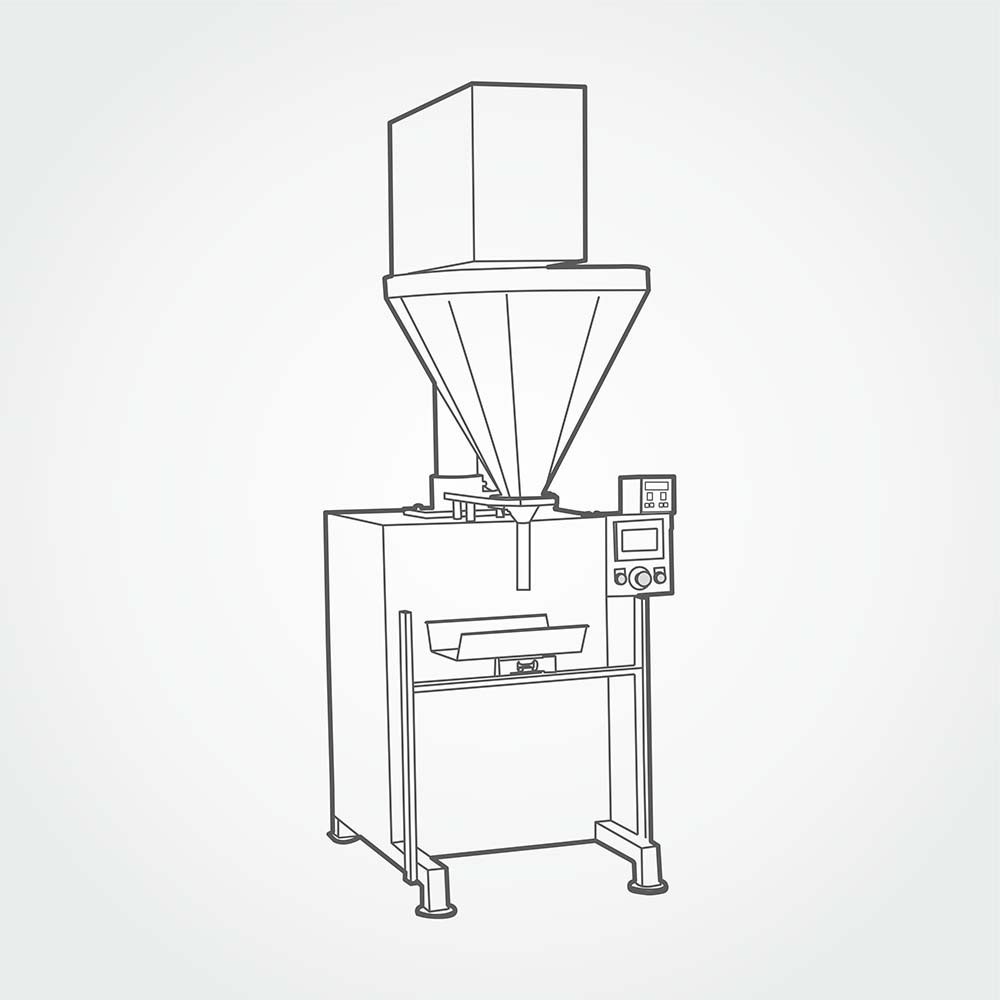

Semi Automatic Powder Filling Machine(Auger Filler)

A pure experience – Get to know our semi-automatic machine.

10 Gram to 1 kg

Filling Range

0.10 +/-

Filling Accuracy

5-30 Pouches

Filling Speed Per Min.

SS-304

Machine Construction

A semi-automatic piston paste filling machine is a versatile piece of equipment designed to accurately dispense viscous substances such as pastes, ketchup, types of oils, gels, cosmetic creams, pharmaceutical paste, sauces, cleaning paste and many more types of pastes into containers. Operated semi-automatically, it typically involves manual placement of containers under the filling nozzle and activation of the filling process, while the machine automatically dispenses the desired amount of product using a piston-driven mechanism. These machines are widely used in industries such as food, cosmetics, pharmaceuticals, chemicals, personal care, home care, automotive and many more for filling various types of containers including jars, bottles, tubes, and pouches. With adjustable filling volumes and precise control mechanisms, semi-automatic piston paste filling machines ensure consistent and reliable filling, enhancing efficiency and productivity in packaging operations.

Suitable Products for These Machines

Coffee Powder

Spices

Protein Powder

Milk Powder

Medicinal Powders

Ayurvedic Powders

And Many More Products

Full Specification And Model Details

PARTICULAR |

SEMI AUTOMATIC POWDER FILLING MACHINE(AUGER FILLER) |

| FILLING CAPACITY | 10 GM – 1.0 KG |

| HOPPER CAPACITY | 40 KG AS PER PRODUCT |

| FILLING SPEED | 5-30 POUCH/MIN AS PER WEIGHT |

| FILLING ACCURACY | 0.10+/- |

| MACHINE CONSTRUCTION | SS-304 |

|

VOLTAGE |

230V/50HZ V SINGLE PHASE/3PHASE |

| K.W | 2000W |

| HMI | DELTA MAKE |

| SERVO MOTOR | 1.5 KW DETLA KINKO/0.5HP |

| LOADCELL CONTROLLER | DELTA MAKE |

| MACHINE WEIGHT | APPROX 250 KG |

Frequently Asked Questions (F.A.Q.s)

1. What is the filling range of semi-automatic powder filling machine?

- The filling range of Semi-automatic Powder Filling Machine is customizable, accommodating weight from 10 grams to 1 kilogram.

2. What type of materials is used in the construction of the machine?

- The Machine comes in two models: one is manufactured from high-quality stainless steel and the second one is manufactured from mild steel.

3. What safety features comes in handy with this machine?

- The machine has safety feature of emergency stop button.

4. Is this machine compatible for single-phase and three-phase power?

- Yes, this machine is compatible for both single-phase and three-phase power systems.

5. What is the storage capacity of the hopper in this machine?

- The hopper of the machine can hold up to 60 kg.

Explore Related Machines

SEMI AUTOMATIC POWDER FILLING MACHINE (AUGER FILLER)

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE 500ML

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE 1000ML

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE WITH STIRRER TANK

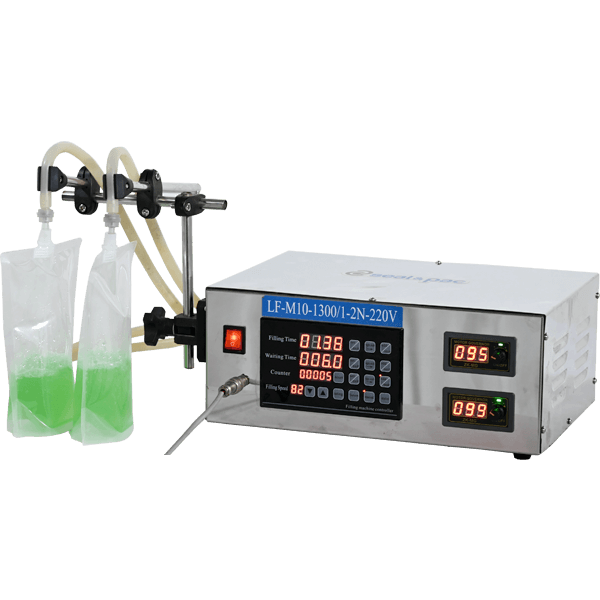

MANUAL LIQUID FILLING MACHINE (TWO HEAD)

GRANULES WEIGHING MACHINE 500GM

GRANULES WEIGHING MACHINE 999GM

GRANULES WEIGHING MACHINE 3KG

GRANULES WEIGHING MACHINE 5KG

SEMI AUTOMATIC VERTICAL BAND SEALING MACHINE WITH NITROGEN FLUSHING

NITROGEN FLUSHING MACHINE

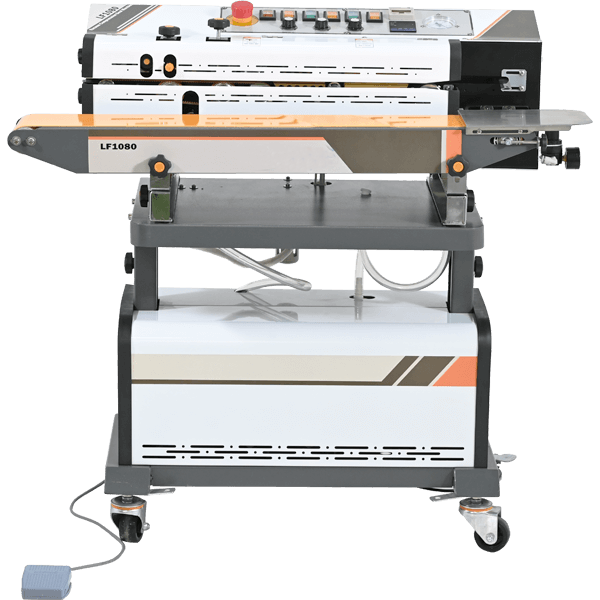

Horizontal Band Sealing Machine 4 In 1

VACUUM CHAMBER SEALING MACHINE – 2D

Table Top Vacuum Chamber Sealing Machine

MANUAL INDUCTION SEALING MACHINE

SEMI AUTOMATIC INDUCTION SEALING MACHINE

shrink wrapping tunnel machine

Handheld Inkjet Batch Coding Machine

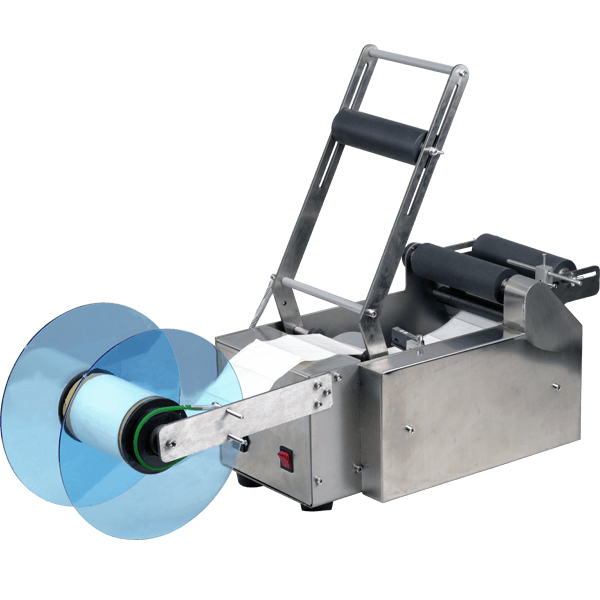

Manual round bottle labelling machine

Semi Automatic round bottle labelling machine

Horizontal band sealing machine

Vertical Band sealing machine

Semi Automatic vertical band sealing machine 25Kg

Foot pedal sealer 450MM

Foot pedal sealer 650MM

Impulse heat sealer 600mm

Impulse heat sealer 800mm

Hand sealer 200mm

Hand sealer 300mm