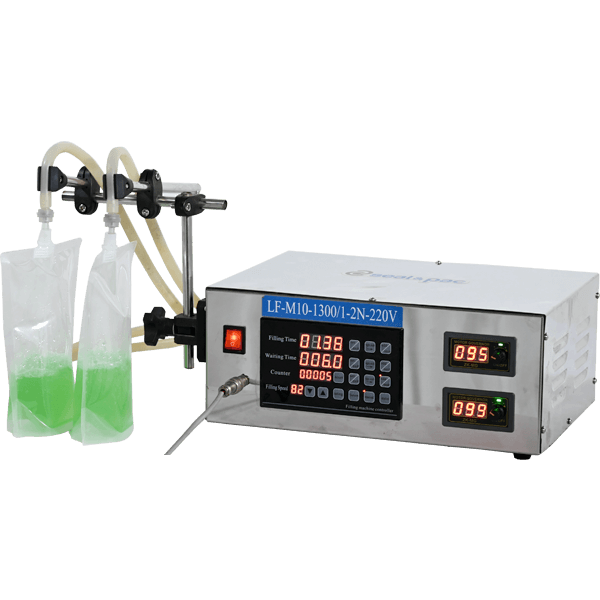

Manual Liquid Filling Machine(Two Head)

A pure experience – Get to know our semi-automatic machine.

10 ML to 3500 ML

Filling Range

0.5 +/-

Filling Accuracy

5-6 Bottles

Filling Speed Per Min.

SS-304

Machine Construction

A manual liquid filling machine is a simple yet effective device used for filling bottles, spout pouches and different types of containers with liquids. It typically consists of a nozzle attached to a reservoir or holding tank for the liquid. Operators manually position the container under the nozzle, then control the flow of liquid by digital display. This allows to regulate the amount of liquid dispensed into each container. These machines are suitable for small-scale production or operations where automation is not feasible or necessary. They are commonly used for filling bottles, spout pouches, jars, vials, and other containers with various types of liquids such as water, oils, juices, energy drinks, milk, hand wash, liquid soap, detergents, syrup, oral medication, hand sanitizer, perfumes, cleaning liquids and more. Manual liquid filling machines are easy to operate, require minimal maintenance, and are cost-effective solutions for businesses with lower production volumes or limited budgets. They offer versatility and flexibility in filling different types of containers and liquids, making them essential equipment in many industries.

Suitable Products for These Machines

Water

Juice

Milk

Soft Drinks

Hand Wash

Cooking oils

Vinegar

Oral Medications

Hand Sanitizers

Cleaning Solutions

Perfumes

Syrups

And Many More Products

Full Specification And Model Details

PARTICULAR |

MANUAL LIQUID FILLING MACHINE (TWO HEAD) |

| FILLING CAPACITY | 10 ML – 3500 ML |

| FILLING SPEED | 5-6 BOTTLES/MIN |

| FILLING ACCURACY | 0.5 + /- |

| CONTROL MODE | MANUAL / AUTO |

| MACHINE CONSTRUCTION | SS-304 |

| POWER SUPPLY | 230V /50 Hz |

| K.W | 200 W |

| MACHINE WEIGHT | Approx 8.00 KG |

Frequently Asked Questions (F.A.Q.s)

Can this machine fill chemicals?

- No, this machine is not designed to fill chemical liquids.

How can the liquid filling machine be configured based on user requirements?

-

The liquid filling machine can be configured to use either a single pipe or dual pipes, depending on the user’s requirements.

Is the height of the filling pipe stand adjustable in the machine?

- Yes, the height of the filling pipe stand in the machine is adjustable according to the container size.

What options are available for the pipes in this machine?

-

This machine offers the flexibility to use either silicon pipes or stainless steel (SS) pipes based on the user preferences and requirements.

Is it possible to adjust the timing gap between filling two containers, either increasing or decreasing it as needed?

-

Yes, we have the flexibility to adjust the timing gap for filling paste according to our specific needs.

Explore Related Machines

SEMI AUTOMATIC POWDER FILLING MACHINE (AUGER FILLER)

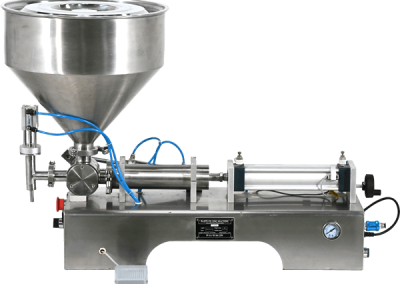

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE 500ML

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE 1000ML

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE WITH STIRRER TANK

MANUAL LIQUID FILLING MACHINE (TWO HEAD)

GRANULES WEIGHING MACHINE 500GM

GRANULES WEIGHING MACHINE 999GM

GRANULES WEIGHING MACHINE 3KG

GRANULES WEIGHING MACHINE 5KG

SEMI AUTOMATIC VERTICAL BAND SEALING MACHINE WITH NITROGEN FLUSHING

NITROGEN FLUSHING MACHINE

Horizontal Band Sealing Machine 4 In 1

VACUUM CHAMBER SEALING MACHINE – 2D

Table Top Vacuum Chamber Sealing Machine

MANUAL INDUCTION SEALING MACHINE

SEMI AUTOMATIC INDUCTION SEALING MACHINE

shrink wrapping tunnel machine

Handheld Inkjet Batch Coding Machine

Manual round bottle labelling machine

Semi Automatic round bottle labelling machine

Horizontal band sealing machine

Vertical Band sealing machine

Semi Automatic vertical band sealing machine 25Kg

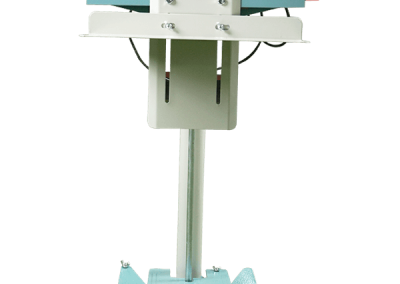

Foot pedal sealer 450MM

Foot pedal sealer 650MM

Impulse heat sealer 600mm

Impulse heat sealer 800mm

Hand sealer 200mm

Hand sealer 300mm