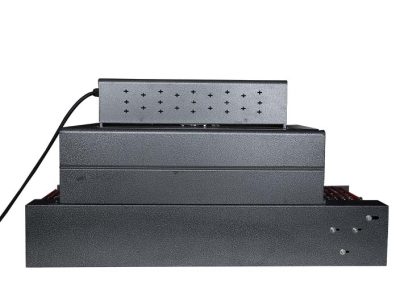

Shrink Wrapping Tunnel Machine

A pure experience – Get to know our semi-automatic machine.

0-10 Meter

Conveyor Speed Per Min

5 kg

Conveyor Capacity

800*260*140 M

Tunnel Size (L*W*H)

Mild Steel (Powder Coated)

Machine Construction

The shrink-wrapping tunnel machine is an essential piece of equipment used for packaging products in shrink wrap film. It consists of a tunnel-like chamber through which products pass on a conveyor belt. Inside the tunnel, heat is applied uniformly to the shrink wrap film, causing it to shrink tightly around the products, creating a secure and professional-looking package. These machines are versatile and can handle a wide range of products and package sizes. They are commonly used in industries such as food, beverage, cosmetics, personal care, pharmaceuticals, printing, retail and many more industries for packaging items like bottles, boxes, trays, books etc. The shrink wrapping tunnel machine offers efficient and consistent packaging solutions, ensuring products are protected and visually appealing for retail display or transportation.

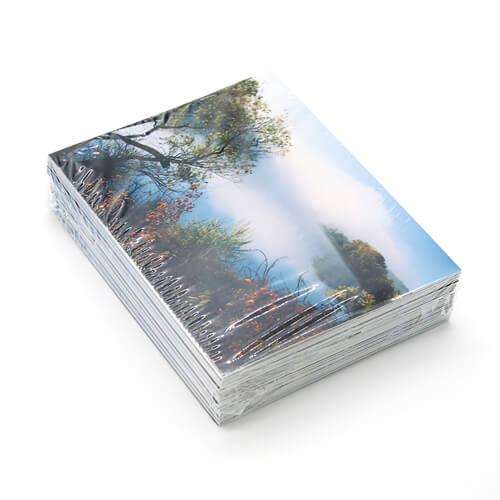

Suitable Products for These Machines

Books

Magazines

Juice Bottle

Soft Drink Cans

Medicine Bottles

Chocolate Box

And Many More Products

Full Specification And Model Details

PARTICULAR |

SHRINK WRAPPING TUNNEL MACHINE |

| MODEL | SHRINK TUNNEL |

| K.W | 220v 50-60Hz |

| POWER | 7.5KW |

| CONVEYOR SPEED | 0-10m/MIN |

| MACHINE CONSTRUCTION | MILD STEEL (POWDER COATED) |

| TUNNEL SIZE(L*W*H) | 800*260*140m |

| CONVEYOR LOADING | 5Kg |

| MACHINE SIZE(L*W*H) | 1120*450*580mm |

Frequently Asked Questions (F.A.Q.s)

What is the primary function of a shrink wrapping tunnel machine?

- A shrink wrapping tunnel machine is primarily used to tightly encase products in plastic film by applying heat, ensuring secure packaging and protection.

Is the shrink wrapping tunnel machine easy to operate?

- Yes, the shrink wrapping tunnel machine is designed to be easy to operate. It typically features user-friendly controls, adjustable settings and straightforward setup procedures, making it accessible for operators with minimal training.

How do I choose the right shrink wrapping tunnel machine for my business?

- To choose the right shrink wrapping machine for your business, consider factors such as production volume, packaging requirements and budgetary constraints. Additionally, consulting with industry experts can provide valuable guidance to ensure you select a machine that meets your specific needs and operational goals.

How does a shrink wrapping tunnel machine work?

- The machine works by feeding the product through a tunnel where heated air or infrared radiation shrinks the film tightly around the product. The heat causes the film to contract and conform to the shape of the item, creating a tight, tamper-evident seal.

Explore Related Machines

SEMI AUTOMATIC POWDER FILLING MACHINE (AUGER FILLER)

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE 500ML

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE 1000ML

SEMI AUTOMATIC PISTON PASTE FILLING MACHINE WITH STIRRER TANK

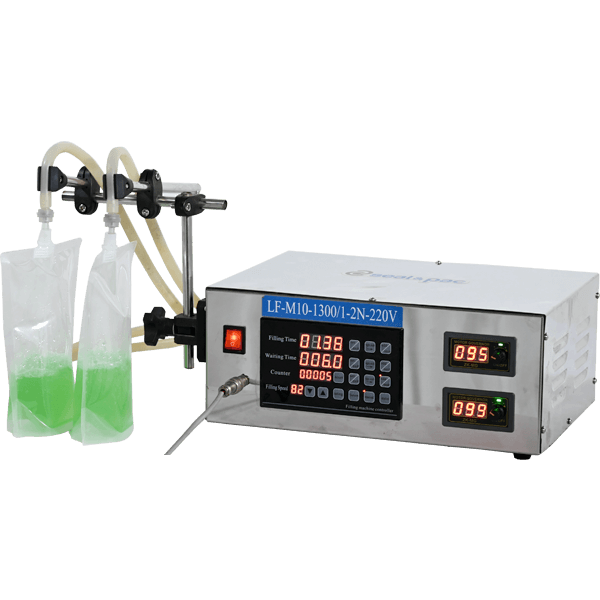

MANUAL LIQUID FILLING MACHINE (TWO HEAD)

GRANULES WEIGHING MACHINE 500GM

GRANULES WEIGHING MACHINE 999GM

GRANULES WEIGHING MACHINE 3KG

GRANULES WEIGHING MACHINE 5KG

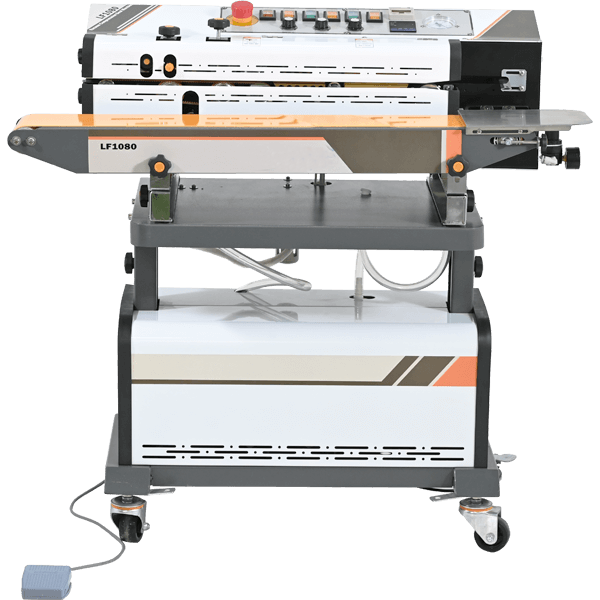

SEMI AUTOMATIC VERTICAL BAND SEALING MACHINE WITH NITROGEN FLUSHING

NITROGEN FLUSHING MACHINE

Horizontal Band Sealing Machine 4 In 1

VACUUM CHAMBER SEALING MACHINE – 2D

Table Top Vacuum Chamber Sealing Machine

MANUAL INDUCTION SEALING MACHINE

SEMI AUTOMATIC INDUCTION SEALING MACHINE

shrink wrapping tunnel machine

Handheld Inkjet Batch Coding Machine

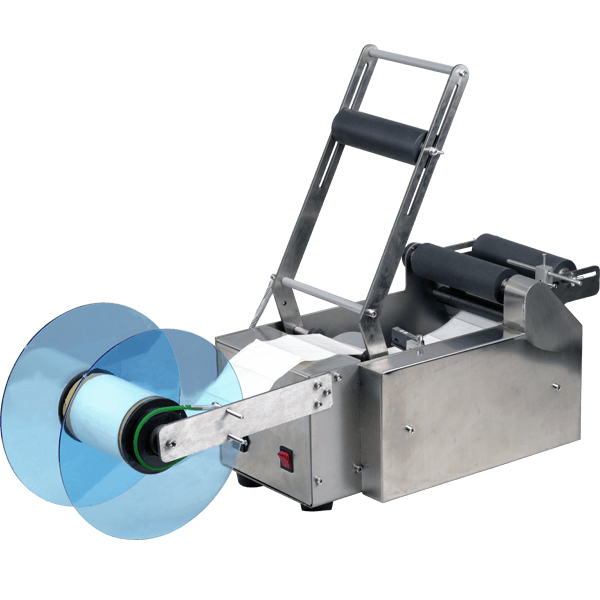

Manual round bottle labelling machine

Semi Automatic round bottle labelling machine

Horizontal band sealing machine

Vertical Band sealing machine

Semi Automatic vertical band sealing machine 25Kg

Foot pedal sealer 450MM

Foot pedal sealer 650MM

Impulse heat sealer 600mm

Impulse heat sealer 800mm

Hand sealer 200mm

Hand sealer 300mm